Strategic sourcing is the continuous procurement process of discovering, prioritizing, improving, and re-evaluating sourcing activities. Read the following 10-step guide to learn about practices that have helped best-in-class companies achieve substantial cost savings and other sourcing objectives.

Traditional Sourcing

Traditionally, procurement has relied on reactive sourcing – responding to requisitions or other business requirements as they come up.

As procurement becomes more proactively managed within a company, reactive sourcing turns tactical. While tactical sourcing involves creating a strategy to anticipate needs and plan accordingly, it still deals with them as they arise.

Strategic Sourcing

Strategic sourcing is a well-planned ongoing process of proactive actions, where procurement takes a leading role in satisfying business needs and adding value to the company.

Actively managing your supply chain means collaborating with internal stakeholders and suppliers, critically analyzing company spend, and managing supplier risks.

The CPO’s Guide to

Strategic Sourcing

If you want to implement strategic sourcing in your organization and have little prior experience, you currently have two options: take extensive coursework through CIPS or ISM or read through hundreds of articles on Google.

To save you time, I’ve put together a comprehensive, step by step guide that you can use to get a better understanding of the principles behind strategic sourcing.

- Increase profit – Every dollar the company saves in procurement goes directly into the P/L bottomline and adds dollars to the profit. Strategic sourcing systematically looks for savings from the whole supply chain, providing the company with a competitive advantage.

- Manage supply risks – Strategic sourcing requires every category of spend and all suppliers to be analyzed. Each existing supplier is evaluated separately for quality risk, financial risk, availability risk, and level of cooperation. Once the risks are identified, you can then take action to avoid or mitigate the risk.

- Improve sustainability – Strategic sourcing is not a one-time project or initiative; it is a continuous cycle of activities. Dedicated category managers within the team will keep an eye on category and supplier performance. With every subsequent cycle, they can go deeper to find additional opportunities to bring value to the company.

- Get more value out of procurement – Strategic sourcing does not mean you are looking solely for quick cost cuts. Every action taken during your strategy implementation is evaluated using the following criteria: Does it provide more value at the same cost, does it decrease operational costs, or does it increase operational speed?

Who should implement strategic sourcing?

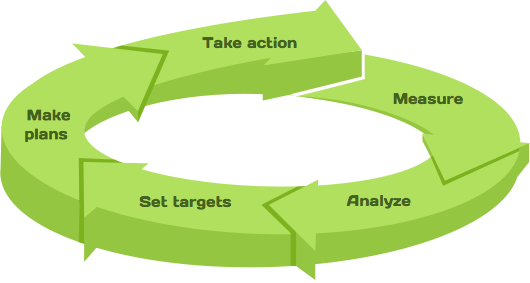

Procurement best practice requires the adoption of strategic sourcing as a guide for developing standardized procurement processes. Strategic sourcing is not a single project but rather a continuous process that rolls like wheel.

Every company who wants to have control over its supply chain should use strategic sourcing principles. Ask yourself this question: Do you control your supply chain or does it control you?

Implementing the best practices of strategic sourcing can provide extra boost to the company’s profit margins. Once your company has grown to the point where you have recruited a procurement manager or supply chain manager, then your company is ready to start implementing strategic sourcing.

The goal is to look beyond daily price and delivery time challenges. Strategic sourcing is a complex process that helps you understand the relationship between your suppliers and your organization.

Written by Peep Tomingas